Enhancing MSEs Sustainable Growth And Competitiveness – EmBRACE

The EmBRACE project is a pilot project that provides financial support to micro and small entrepreneurs within the Interreg VI-A Programme IPA Croatia – Bosnia and Herzegovina – Montenegro 2021-2027 and improves the competitiveness of micro and small enterprises (MSEs) in the border area. MECOnet is partners with ADP ZID on this project.

The project is co-financed by ERDF and IPA III funds of the European Union.

The project’s website: https://cbchb.eu/cbc-cro-bih-mne/embrace/

MECOnet’s role

MECOnet was assigned to this project is to assist in integrating cutting-edge automation solutions, which will allow the agriculture tool to navigate and perform tasks autonomously. This will ensure that the tool functions efficiently and meets the diverse needs of small-scale farmers.

Project’s Timeline

15.5.2025

The initial project meeting took place, where MECOnet representatives Prof. dr Radovan Stojanović and Jovan Đurković were introduced to the project’s aims and challenges. The cooperation between MECOnet and ADP ZID was agreed on.

23.6.2025

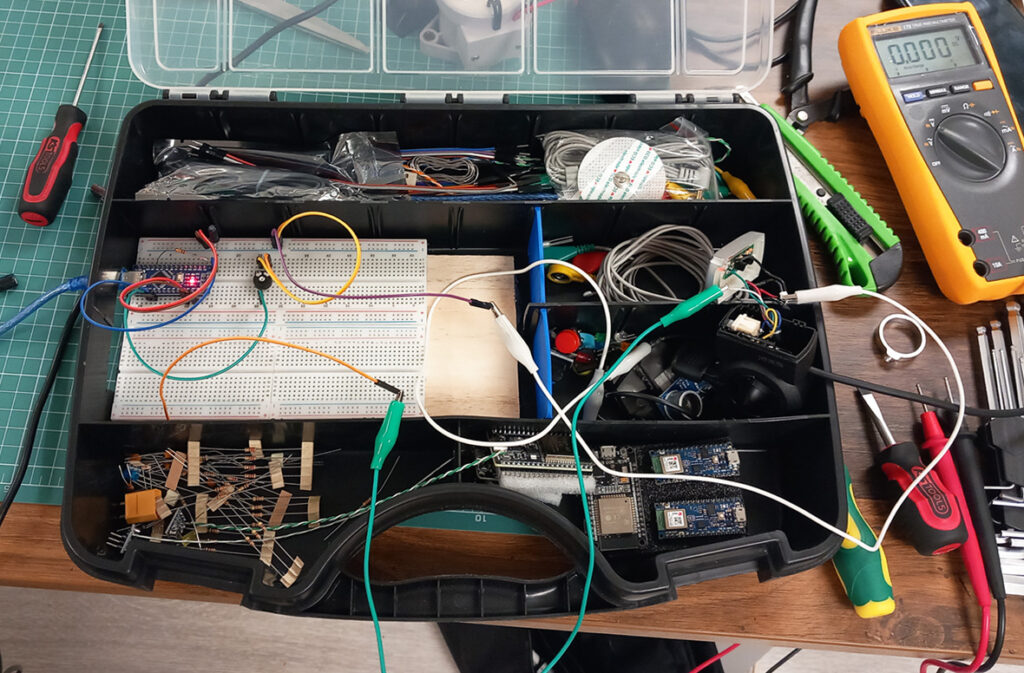

The first practical meeting was held in I2 Space workshop. Hosted by I2 Space manager Vukašin Rakočević, MECOnet team members Jovan Đurković and Dejan Zejak got familiar with the exact equipment necessary for the agriculture tool. The best approaches to solve the automation problem have been considered, and task priority list was created.

7.8.2025

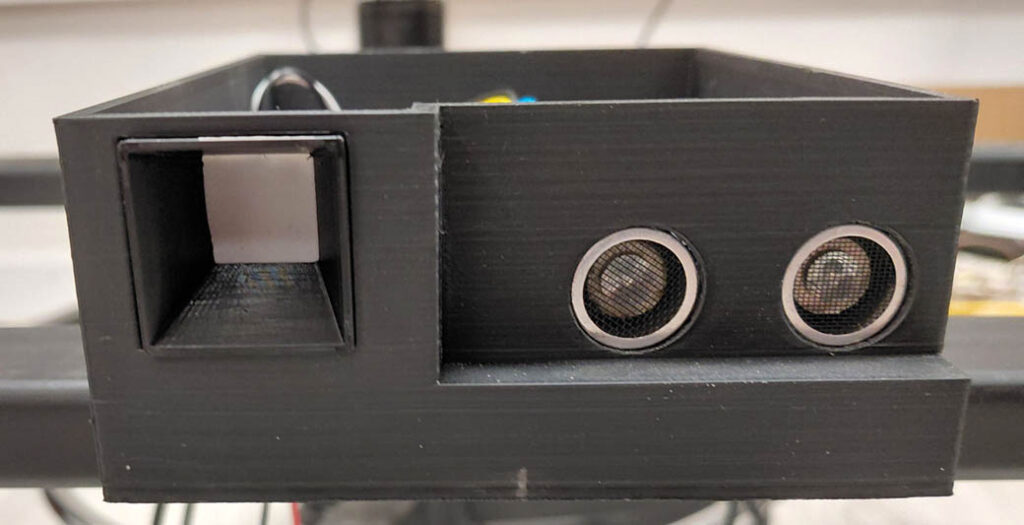

The first task of controlling the machine’s motor using microcontroller was successfully solved and demonstrated on the equipment. The motor’s movement speed could be adjusted by a microcontrolller, which has opened the possibility to further gain control of a machine by implementing steering possibility using 2 motors, as well as the automatic movement. Te wheel is mounted on a MT612T Electric Wheelbarrow Motor which was designed for big torque but relatively low speed.

19-20.1.2026

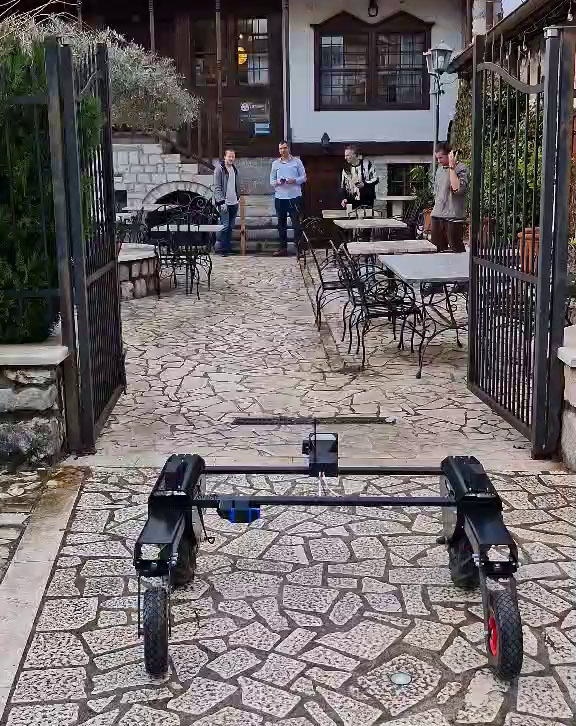

Testing of the first fully assembled prototype. After some debugging and a few tweaks, the manual control is fully operable with an option to switch between two gears. The laser following system works as expected in the laboratory conditions, and the work on stabilizing it’s behavior in the field is in the process.

The manual controller uses radio communication to control the machine, while the builtin camera looks for the laser beam and steers the machine straight towards it when in auto mode.

30.1.2026

The final project presentation was held in Upbeat Hub, where the partners have discussed about the project outcomes. The machine’s operation was demonstrated, including both manual and autonomous drive.